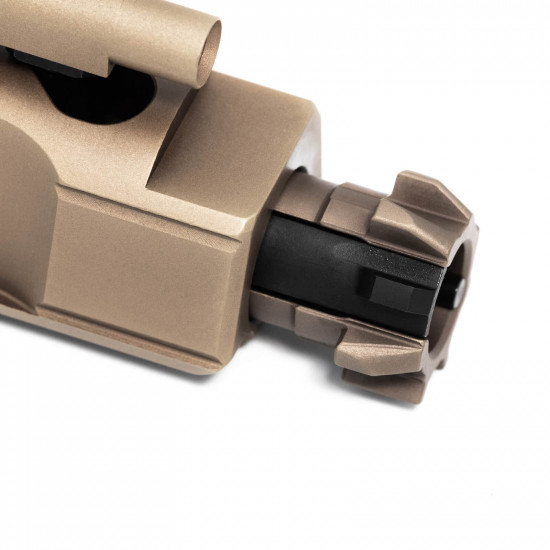

Xtreme Performance Bolt (XPB) Carrier Group in FDE (Flat Dark Earth) Carrier and FDE Bolt

5.56 FULL AUTO BCG

Related products

Description

The Sharps Xtreme Performance Bolt (XPB) Carrier Group Complete is comprised of our patented Relia-Bolt™ and our Balanced Bolt Carrier. Both are machined out of S7 tool steel. The XPB undergoes a 24-hour thermal cycle proprietary heat treatment, and is finished with the FDE (Flat Dark Earth) ZrN (Zirconium Nitride) Coating.

The XPB carrier displays the SRC logo machine cut and is visible when the ejection port door is open. The XPB fits standard AR-15/M16/M4 rifles chambered in .223/5.56, Sharps 25-45, and 300 Blackout calibers.

Technical Specification

Bolt: | S7 Tool steel, shot peened and ZrN coated (U.S. Patent No. 9,863,729) |

Bolt Carrier: | S7 Tool steel, shot peened and ZrN coated |

Gas Key: | 4130 Steel, attached with Grade 8 hardware, properly staked and ZrN Coated |

Cam Pin: | 4340 Steel, Manganese Phosphate coated |

Firing Pin: | Mil Spec firing pin made of 8740 steel, center‐less ground and Hard Chrome coated |

Extractor: | 4340 Steel, Manganese Phosphate coated |

Ejector: | S7, shot peened and Manganese Phosphate coated |

Extractor Pin: | S7, shot peened and Manganese Phosphate coated |

Why S7 Tool Steel?

S7 has excellent shock absorbing properties which provide superior impact resistance when being utilized in the construction of Sharps Bolt Carrier Groups. S7 demonstrates high strength and toughness as well as a resistance to softening at moderately high temperatures, i.e. operating temperatures not exceeding 1000°F.

The properties we as shooters look for in an AR platform BCG, are hardness and wear resistance. S7 provides such attributes when heat-treated properly. Sharps has found that the key benefits from S7 tool steel are higher tensile strength and toughness which translate to longevity of use, i.e., a higher number of cycles the bolt can handle before it fails.

Technical Data on ZrN Coating

Coating thickness: | 2-5 μm (Micro Meter) or 2-5 μ (Microns) |

Hardness HV 0.05: | 1500-1800 or 70+ HRC |

Deposition method: | PVD UBM/PACVD |

Friction vs. steel, dry: | 0.5 |

Color: | Flat Dark Earth |

MPI and HPT tested

Mil-Spec Extractor and Ejector Springs, Firing Pin Retaining Pin, Gas Rings

Tensile strengths of 1550-1600 mpa, or 220,000-235,000 psi.

Toughness of over 200 ft./lb. Charpy C-Notch

HRC of 46 yields a 15% increase in hardness at the same toughness comparing to Carpenter 158 & 9310

Limited Lifetime Warranty

If any SRC Bolt Carrier or Relia-Bolt™ is found to have manufacturer defects, SRC will repair or replace it at no charge. Manufacturer defects include out of spec parts and defective parts. Although our BCG is Mil-Spec, there are so many variables, sometimes a little troubleshooting, or fine tuning of parts may be required for proper functionality. Before a part is replaced or refunded, SRC reserves the right to inspect and test part(s) in question to determine if it is defective. Please keep in mind that altering the product renders the warranty void.